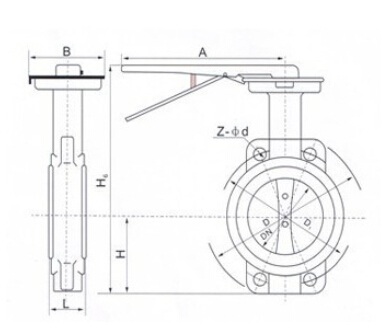

D71J Wafer rubber lined butterfly valve

D71J Wafer rubber lined butterfly valve Product introduction

D71J Wafer Rubber Lined Butterfly Valve is used in on-off and control flow of medium in vaired pipelines such as foodstuff,beverage,machine,chemical engineering,industrial enviromental proction,water treatment and building ect .Flanged rubber seat butterfly valve: ANSI, DIN, JIS, GB, etc.

D71J Wafer Rubber Lined Butterfly Valve Usage

|

Sealing Ring Material Code |

Applicable Temperature |

Applicable Medium |

|

NR |

≤85°C |

water, air, acid-base |

|

CR |

≤85°C |

water, gas, acid-base |

|

NBR |

≤100°C |

water, oil |

|

EPDM |

≤120°C |

water, steam, acid-base |

|

FKM |

≤150°C |

water, steam, strong acid-base |

D71J Wafer rubber lined butterfly valve Technical parameters

| Description | Standard |

| Design and manufacture | EN593 |

| Face to face | ISO5752 series14, EN558-1 series 14, DIN3202 F4 |

| Flange and drilling | ISO7005-2, EN1092, |

| Pressure test | EN12266 |

| Top flange of bare shaft valve | ISO5211 |

| Top flange on worm gearbox for e-actuator | ISO5210 |

D71J Wafer rubber lined butterfly valve Main connection dimensions

| Name | Material |

| Body | ductile cast iron, WCB, stainless steel |

| Disc | ductile cast iron, WCB, stainless steel, Al-bronze |

| Stem | SS420, SS431 |

| Disc seat ring | EPDM,NBR,VITON |

| Body seat ring | SS304 |

| Retainer | SS304, SS316 |

| Shaft bearing | Al-bronze, self-lubricating bearing |

| Bolt & nuts | 8.8 grade galvanized, SS304 |

| Coating | epoxy coating, thickness: min. 250 microns, color code: RAl5015, 5017, 5010, and etc. |

D71J Wafer rubber lined butterfly valve Main dimension

|

DN(mm) |

PN(MPa) |

Working Temperature(MPa) |

L |

D |

D1 |

n-Φd |

H1 |

H2 |

S |

H3 |

Weight Kg/kilos |

|

40 |

1.6 1.0 |

1.6 1.0 |

33 |

150 |

110 |

4-18 |

55 |

100 |

235 |

27 |

2 |

|

50 |

43 |

165 |

125 |

4-18 |

64 |

120 |

235 |

27 |

2.5 |

||

|

65 |

46 |

185 |

145 |

4-18 |

80 |

120 |

235 |

27 |

4.5 |

||

|

80 |

46 |

200 |

160 |

8-18 |

112 |

130 |

265 |

27 |

5.5 |

||

|

100 |

52 |

220 |

180 |

8-18 |

90 |

145 |

265 |

27 |

6.5 |

||

|

125 |

56 |

250 |

210 |

8-18 |

112 |

160 |

365 |

32 |

11.5 |

||

|

150 |

56 |

285 |

240 |

8-22 |

135 |

175 |

365 |

32 |

13.5 |