AWWA C504 Butterfly Valve

AWWA C504 Butterfly Valve Product introduction

AWWA C504 Butterfly Valve Technical parameters

|

Nominal Diameter

|

DN50(2 inch)~DN600(24 inch)

|

mm(inch)

|

||

|

Nominal Pressure

|

PN10

|

PN16

|

MPa

|

|

|

Test Pressure

|

Sealing

|

1.1

|

1.76

|

|

|

Shell

|

1.5

|

2.4

|

||

|

Working Temperature

|

-15~+150(C)

|

|||

|

Suitable Medium

|

Fresh water, Sewage, Sea water, Air, Vapour, Food, Medicine, Oils, Acids, Alkalis etc..

|

|||

|

Actuator

|

Lever, Gear box, Pneumatic or Electric actuator

|

|||

AWWA C504 Butterfly Valve Main connection dimensions

|

No.

|

Parts

|

Materials

|

|

1

|

Body

|

CI+EPDM/NBR

|

|

DI+ EPDM/NBR

|

||

|

2

|

Bushing

|

Lubrized Bronze

|

|

F4-PTFE

|

||

|

3

|

Shaft

|

Stainless Steel

|

|

4

|

Disc

|

DI, AL-bronze, Stainless steel

|

|

5

|

Taper pin

|

Stainless Steel

|

|

6

|

O-ring

|

Rubber

|

|

7

|

Key

|

Steel 45

|

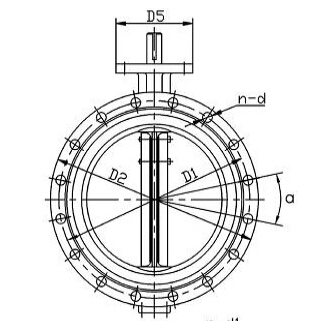

AWWA C504 Butterfly Valve Main dimension

|

Size

|

A

|

B

|

C

|

D

|

D1

|

D2

|

D3

|

D5

|

L

|

L1

|

n-d

|

a

|

f

|

n-d

|

Weight

|

|

DN50

|

83

|

120

|

20

|

52.9

|

125

|

165

|

99

|

77

|

108

|

111

|

4-19

|

90

|

3

|

4-7

|

7.6

|

|

DN65

|

93

|

130

|

20

|

64.5

|

145

|

185

|

118

|

77

|

112

|

115

|

4-19

|

90

|

3

|

4-7

|

9.7

|

|

DN80

|

100

|

145

|

22

|

78.8

|

160

|

200

|

132

|

77

|

114

|

117

|

8-19

|

45

|

3

|

4-7

|

10.6

|

|

DN100

|

114

|

155

|

24

|

104

|

180

|

220

|

156

|

92

|

127

|

130

|

8-19

|

45

|

3

|

4-10

|

13.8

|

|

DN125

|

125

|

170

|

26

|

123.3

|

210

|

250

|

184

|

92

|

140

|

143

|

8-19

|

45

|

3

|

4-10

|

18.2

|

|

DN150

|

143

|

190

|

26

|

155.6

|

240

|

285

|

211

|

92

|

140

|

143

|

8-23

|

45

|

3

|

4-10

|

21.7

|

|

DN200

|

170

|

205

|

26

|

202.5

|

295

|

340

|

266

|

115

|

152

|

155

|

8-23

|

45

|

3

|

4-12

|

31.8

|

|

DN250

|

198

|

235

|

28

|

250.5

|

350

|

395

|

319

|

115

|

165

|

168

|

12-23

|

30

|

3

|

4-12

|

44.7

|

|

DN300

|

223

|

280

|

28

|

301.5

|

400

|

445

|

370

|

140

|

178

|

182

|

12-23

|

30

|

4

|

4-14

|

57.9

|

|

DN350

|

279

|

310

|

30

|

333.3

|

460

|

505

|

429

|

140

|

190

|

194

|

16-23

|

22.5

|

4

|

4-14

|

81.6

|

|

DN400

|

300

|

340

|

32

|

389.6

|

515

|

565

|

480

|

197

|

216

|

221

|

16-28

|

22.5

|

4

|

4-18

|

106

|

|

DN450

|

345

|

375

|

32

|

440.5

|

565

|

615

|

530

|

197

|

222

|

227

|

20-28

|

18

|

4

|

4-18

|

147

|

|

DN500

|

355

|

430

|

34

|

491.6

|

620

|

670

|

582

|

276

|

229

|

234

|

20-28

|

18

|

4

|

4-22

|

165

|

|

DN600

|

410

|

500

|

36

|

592.5

|

725

|

780

|

682

|

276

|

267

|

272

|

20-31

|

18

|

5

|

4-22

|

235

|

|

DN700

|

478

|

560

|

40

|

695

|

840

|

895

|

794

|

300

|

292

|

299

|

24-31

|

15

|

5

|

8-18

|

338

|

|

DN800

|

529

|

620

|

44

|

794.7

|

950

|

1015

|

901

|

300

|

318

|

325

|

24-34

|

15

|

5

|

8-18

|

475

|

|

DN900

|

584

|

665

|

46

|

864.7

|

1050

|

1115

|

1001

|

350

|

330

|

338

|

28-34

|

12.9

|

5

|

8-22

|

595

|

|

DN1000

|

657

|

735

|

50

|

965

|

1160

|

1230

|

1112

|

350

|

410

|

417

|

28-37

|

12.9

|

5

|

8-22

|

794

|

|

DN1200

|

799

|

917

|

56

|

1160

|

1380

|

1455

|

1328

|

415

|

470

|

478

|

32-41

|

11.3

|

5

|

8-33

|

1290

|

|

DN1400

|

920

|

1230

|

62

|

1393.7

|

1590

|

1685

|

1530

|

415

|

530

|

538

|

36-43

|

10

|

5

|

8-33

|

2211

|