pneumatic flanged butterfly valve

pneumatic flanged butterfly valve Product introduction

Design standard conform to: MSS SP-67, API609, EN593

Connection flange conform to: DIN PN10/16/25, ANSI B16.1, BS4504, ISO PN10/16,

JIS B2212/2213, BS 10 Table D, BS 10 Table E

Top flange conform to: ISO 5211

Face to face conform to: API609, ISO5752 series 20, BS5155

Test standard conform to: API598

wafer type corrosion resistant butterfly valves design characters:

1.Correcting holes are made on flange according to standard, easy correcting during the installation.

2.Through-out bolt or one-side bolt used. Easy replacing and maintenance.

3.Shaft and disc connected by pin, torque screw or non pin, to achieve the opening and closing.

wafer type corrosion resistant butterfly valves performance:

Nominal Diameter:DN50-DN1200

Nominal Pressure PN (MPa): 1.0, 1.6, 2.0, 2.5

Testing pressure (water) Ps (MPa)

Body seat: 1.5 times rated pressure

Seat test: 1.1 times rated pressure

pneumatic flanged butterfly valve Technical parameters

| Description | Standard |

| Design and manufacture | EN593 |

| Face to face | ISO5752 series14, EN558-1 series 14, DIN3202 F4 |

| Flange and drilling | ISO7005-2, EN1092, |

| Pressure test | EN12266 |

| Top flange of bare shaft valve | ISO5211 |

| Top flange on worm gearbox for e-actuator | ISO5210 |

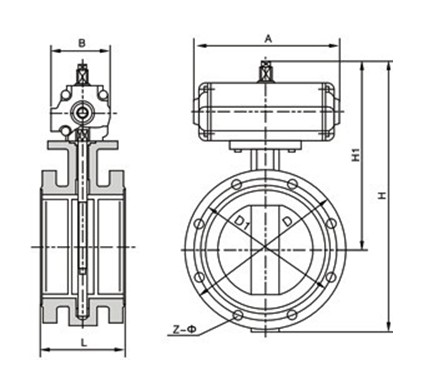

pneumatic flanged butterfly valve Main connection dimensions

| Name | Material |

| Body | ductile cast iron, WCB, stainless steel |

| Disc | ductile cast iron, WCB, stainless steel, Al-bronze |

| Stem | SS420, SS431 |

| Disc seat ring | EPDM,NBR,VITON |

| Body seat ring | SS304 |

| Retainer | SS304, SS316 |

| Shaft bearing | Al-bronze, self-lubricating bearing |

| Bolt & nuts | 8.8 grade galvanized, SS304 |

| Coating | epoxy coating, thickness: min. 250 microns, color code: RAl5015, 5017, 5010, and etc. |